Preview the Reusable Packaging Pavilion at Pack Expo: Part 3

We’ve got a great lineup waiting for you at the Reusable Packaging Pavilion at Pack Expo taking place September 23-25 in Las Vegas. 35 exhibitors of reusable transport packaging products and related services and the Reusable Packaging Learning Center, where you can learn about the latest sustainable packaging trends and supply chain solutions from industry experts on Monday and Tuesday from 11am – 3pm.

Here’s even more of what the RPA Pavilion has to offer:

PTM (Booth # 7912) is looking for constant improvement. Starting from the Ultra Pallet, our first generation of pallets we evolved to the Stamina Pallet 48”x40”. It has strategic features for the operation; it is made with Stamina blocks, this design increase resistance for forklift impacts. With aluminum inserts to increase deflection resistance and weighs less than 50 pounds, offers greater load capacity and versatility in the operation. These pallets are designed for material handling for traditional or highly automatized supply chain.

Stamina Pallet Features:

- Top deck anti slip pads inserted with double injection.

- Unique structural block design for impact endurance

- Plastic parts joined by hotplate welding to provide exceptional rigidity

- Bottom deck with optional metal reinforcement

- Encapsulated metal reinforcement to prevent rust

- Smooth surface design to facilitate cleaning

With this pallet durability, PTM reinforces the commitment to the environment reducing the amount of carbon emissions generated by the constant use of wooden pallets.

Girton Manufacturing Co., Inc. (Booth # 8011) has been family owned and operated since 1927; and, with 48% of the Girton workforce possessing at least 10 years of tenure with the company, Girton Manufacturing Co., Inc. is confident in its manufacturing capabilities. Girton is a global supplier of stainless steel washing equipment which includes cabinet washers, conveyorized systems, and COP tanks that are specially designed for the food and dairy, pharmaceutical production and research, and laboratory animal care industries. Each piece of equipment is custom designed to fit the end users’ needs which include washing bins, drums, pallets, totes, trays, dollies, glassware, cages, vials and IBC’s.

In addition to being a leader in the washing industry, Girton also produces the well-known brand of ice builder – the King Zeero. With 275 different models, these ice builders can be easily designed to fit into most liquid cooling processes.

Contact Girton to help you with you washing and cooling needs!

InterCrate (Booth # 8213) is a family owned company focused on constructing rigid and collapsible containers for fresh produce and food industries. We build InterCrate containers for performance. With three-generations of plastic container design and production expertise, we specialize in problem solving to improve process efficiency. Our innovative containers are designed to protect produce, increase efficiency in the supply chain and deliver quality goods to the end user. Using the latest in technology, we make sure that your produce is delivered fresh from the farm.

Our InterCrate 4.5 container has been used primarily as a harvest container in the production of blueberries. The design of this container’s ventilation pattern provides rapid cooling once out of the field and into cold storage rooms. The faster that you can cool freshly picked blueberries, the longer the shelf life of that fruit will be.

Our InterCrate FreshTote container was developed with a leading salad grower/packer and is used in salad harvest and processing operations. The FreshTote is simply the toughest, most break resistant harvest tote available, and comes with our proprietary metal detection additive which allows plastic debris to be detected in fresh cut operations.

TriEnda (Booth # 8108) For more than four decades, TriEnda has led the way in material handling and cargo solutions. One of the largest industrial plastics manufacturers in North America, TriEnda is known for its innovative solutions and custom products. From prototype to production, it serves diverse self-palletized markets like automotive, agriculture, government, grocery, food and beverage, and many more.

At PACK EXPO, TriEnda will feature:

- Hygienic Thermoformed Pallet

Tough Pallet by TriEnda is the first thermoformed rackable, nestable pallet made of high-density polyethylene (HDPE). Sanitary, durable, and lightweight, Tough Pallet has a unique design that enables companies to minimize required storage space and reduce shipping costs. - Nestable Pallets featuring TruGrip™

TruGrip™ is the latest technology from TriEnda. With an anti-skid surface, it’s a one-of-a-kind solution that keeps products safe, secure, and reduces damage. - Cargo Protection Systems

Industry-tested cargo protection systems by TriEnda help decrease in-transit load shift and provide superior product protection during transit via rail, truck, and ship. These lightweight, user-friendly solutions result in a lower average cost per load.

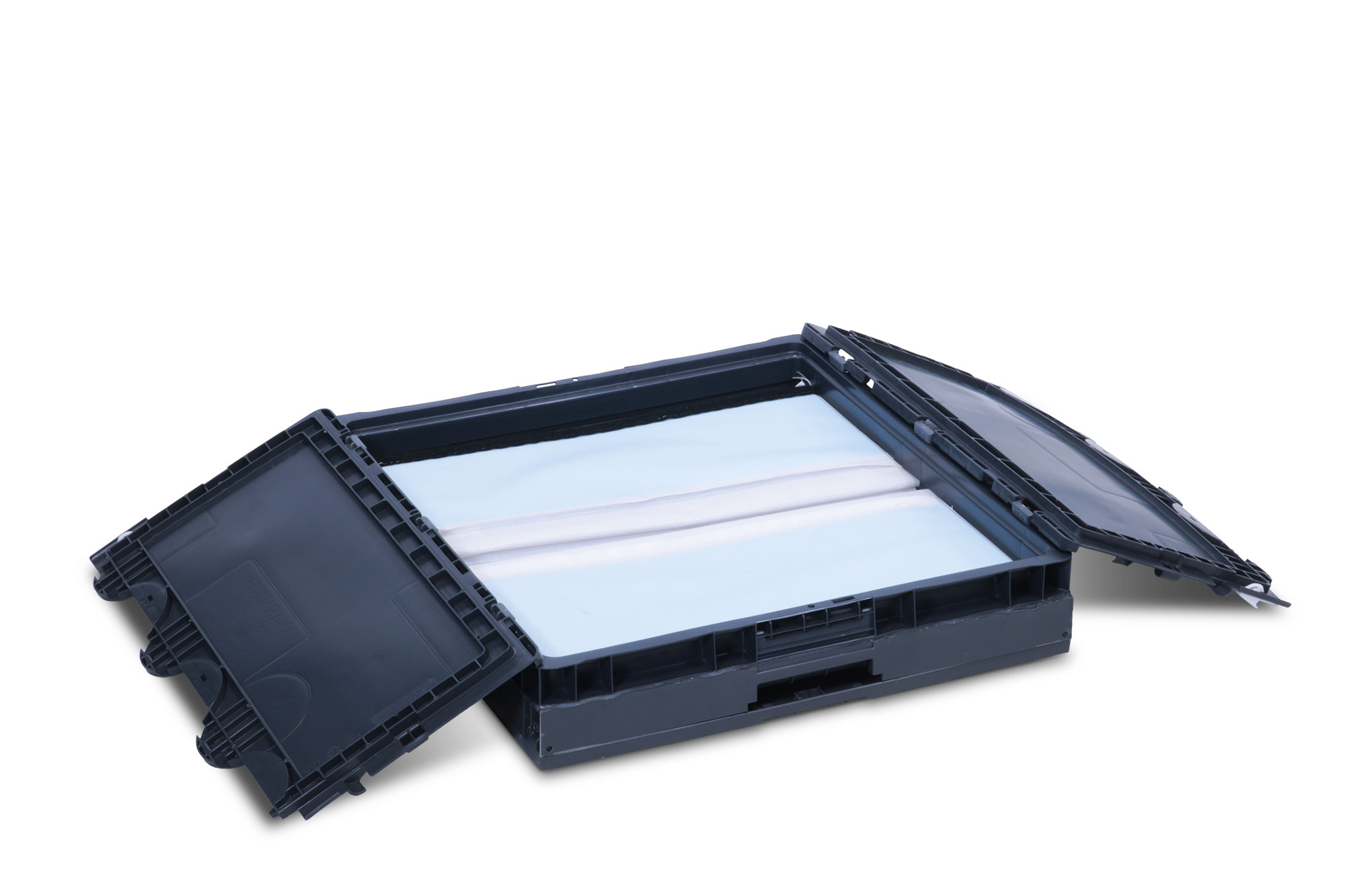

Schaefer (Booth # 8205), a leader in reusable packaging systems, will be introducing foldaway, space-saving dunnage material that works seamlessly with the SSI SCHAEFER collapsible CF handheld tote series. This new-patented combination is an unbeatable feature for industries looking to ship parts and return collapsed containers without having to remove the dunnage.

The CF collapsible container system is compatible with both 48” x 45” systems on the market. In addition, the handheld system comes in three different bottom designs for smooth, Crosspad®, and Crosstac, as well as an optional lid. Standard sizes start at 12” x 15”, 24” x 15”, and 24” x 22” but custom sizes are available for specific applications. The dunnage material is made of sewn textiles from the SCHAEFGUARD® dunnage product portfolio. Designed to maximize part to container ratio along with multiple material options translate to lower freight costs and more returned containers per truckload.

Check out our Pack Expo Preview Part 1 and Part 2 for more on the exciting solutions you’ll see in the Reusable Packaging Pavilion at Pack Expo 2019!