The synergy between automation and reusables is well established. For example, in manufacturing plants, reusable packaging systems have long played a critical role in presenting precise part placement to facilitate removal by a robot. At the dairy, for decades, the reusable crate has fit the bill as a robust, uniform, and moisture-resistant container that can be handled flawlessly by conveyor or at the automated palletizer. While the connection between automation and reusables has been proven over time, however, the two are now poised to reach new heights with market forces now accelerating the rate of automation uptake.

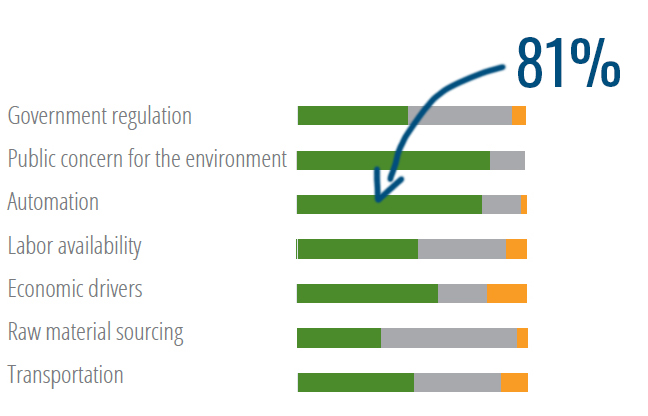

The growing relationship between automation and reusables was underscored by the Reusable Packaging Association’s State of the Industry 2020 report. In a survey that immediately preceded the Covid-19 pandemic, a majority of respondents (81%) were optimistic that the demand for reusables would increase over the next five years due to the growing automation trend. And, of course, the Covid-19 pandemic has even further accelerated the shift to online shopping and automation projects.

MarketsandMarkets™ estimates the market for logistics sector automation to reach $88.9 billion by 2026, up from $48.4 billion in 2020 and boasting a Compound Annual Growth Rate (CAGR) of 10.6% during the forecast period.

These systems include Automated Storage and Retrieval System (ASRS), conveyors and sortation systems, robotic handling systems, Autonomous Mobile Robots (AMRs), and Automated Guided Vehicles (AGVs). The trend has been fueled by the factors such as the growth of e-commerce, warehouse space shortages, labor availability, and the need for inventory accuracy and rapid execution.

Highly durable reusables, including pallets, bulk bins, trays, totes, and other containers, are valued for characteristics such as high dimensional accuracy, stiffness, and other features that ensure the reliable performance of automated equipment. Additionally, the cost-effective integration of technology such as connected IoT devices into reusables can help transform the automated warehouse into a smart warehouse.

On the other hand, single-use or limited-use packaging can prove problematic in automation. For example, susceptibility to moisture, box deformation, pallet damage, and other quality concerns can disrupt operations. To the latter point, a 2019 survey by Modern Materials Handling found that poor quality bottom pallet deck boards were a significant cause of jams or faults in storage systems, with a whopping 53% of respondents dealing with this issue on a daily or weekly basis. Another 25% of participants experienced this problem at least monthly.

Custom totes for a customer’s highly automated processes from SSI Schaefer

Explore Reusables Early in the Automation Project

In the past, containers and pallets have only been considered in the final stages of an automation project rather than inception. As a result, reusable packaging vendors have been called upon to create custom products to fit the application. While many RPA-member companies excel in building unique fit-for-purpose products, such an approach can result in needless extra expense compared to using a standard container or pallet. To avoid unnecessary costs or delays, vendors of reusables encourage customers to bring them into the project during the early stages.

Micro Fulfillment Centers and Reusables

When it comes to the uptake of automated systems, one of the hottest categories is the retail micro-fulfillment center (MFC). Such systems allow for the cost-effective picking of customer orders by retrieving goods from storage and presenting them to the order picker. MFCs rely on standardized reusable containers, thus eliminating the inefficient travel time required for conventional picking and speeding up the process to allow for more timely delivery. Experts predict that the MFC market will grow from $1 billion in 2022 to $10 billion by 2026.

Schoeller Allibert’s Maxinest eTail Tote

ORBIS Corp.‘s Mini-Load Container for automated warehouses

CABKA‘s Pallet Box in use in a customer’s fully automated food processing facility.

Automated Storage and Retrieval Systems

Manufacturing plants, warehouses, and distribution centers install Automated Storage and Retrieval Systems (AS/RS) for storing and retrieving loads from one storage location to another. Pallet AS/RS systems generally rely on high-quality, dimensionally accurate pallets to ensure reliable performance. Bulk container AS/RS use plastic bulk bins and are used for work in progress or bulk staging for products ranging from ingredients to root crops to pet food. Other types of AS/RS such as mini-load systems, gantry robots, and other technologies rely on standardized reusable containers or trays to ensure reliable functionality. In the perishable sector, reusable containers such as RPCs are increasingly being utilized in automated warehouses for the storage and order assembly of products such as fresh produce and meat products.

Autonomous Forklifts and Pallet Quality

Watch for the autonomous forklift market to also enjoy solid growth – a CAGR of 7.14% up to 2027, reaching a value of $12.2 billion. Driverless forklifts help reduce labor requirements, never phone in sick, and increase plant safety. Some mobile robots used to shuttle pallets are very flexible regarding quality – they serve as a base that the pallet can be set upon. However, autonomous forklifts enter pallets with forks. Therefore, broken boards or inconsistencies can prevent a clean entry. A shift to autonomous lift trucks will require close attention to pallet quality through investment in more durable pallets or more frequent quality inspections to ensure the removal of damaged units.

iGPS pallet for automated storage and retrieval systems (ASRS)

CHEP’s pooled wooden block pallet

RM2′s fiberglass composite block pallet

HOREN CoRTP’s EUO crates in a customer’s automated warehouse

Mission Critical and the Shift to Automation

High-quality, dimensionally accurate pallets, and containers are often needed to optimize the performance of sophisticated automated systems. With the Covid-19 pandemic accelerating the shift to Industry 4.0, reusables, increasingly fitted with IoT sensors, will be essential partners in this transformation. From MFCs to automated warehouses to autonomous forklifts and more, it will be necessary for adopters of automation to bring reusable packaging suppliers into the conversation early. Recognizing the critical interplay between reusable packaging and automated equipment will help ensure a seamless implementation of the new wave of logistics automation.